SPECIFICATION GENERATOR

Find out which low impact materials are right for your building project.

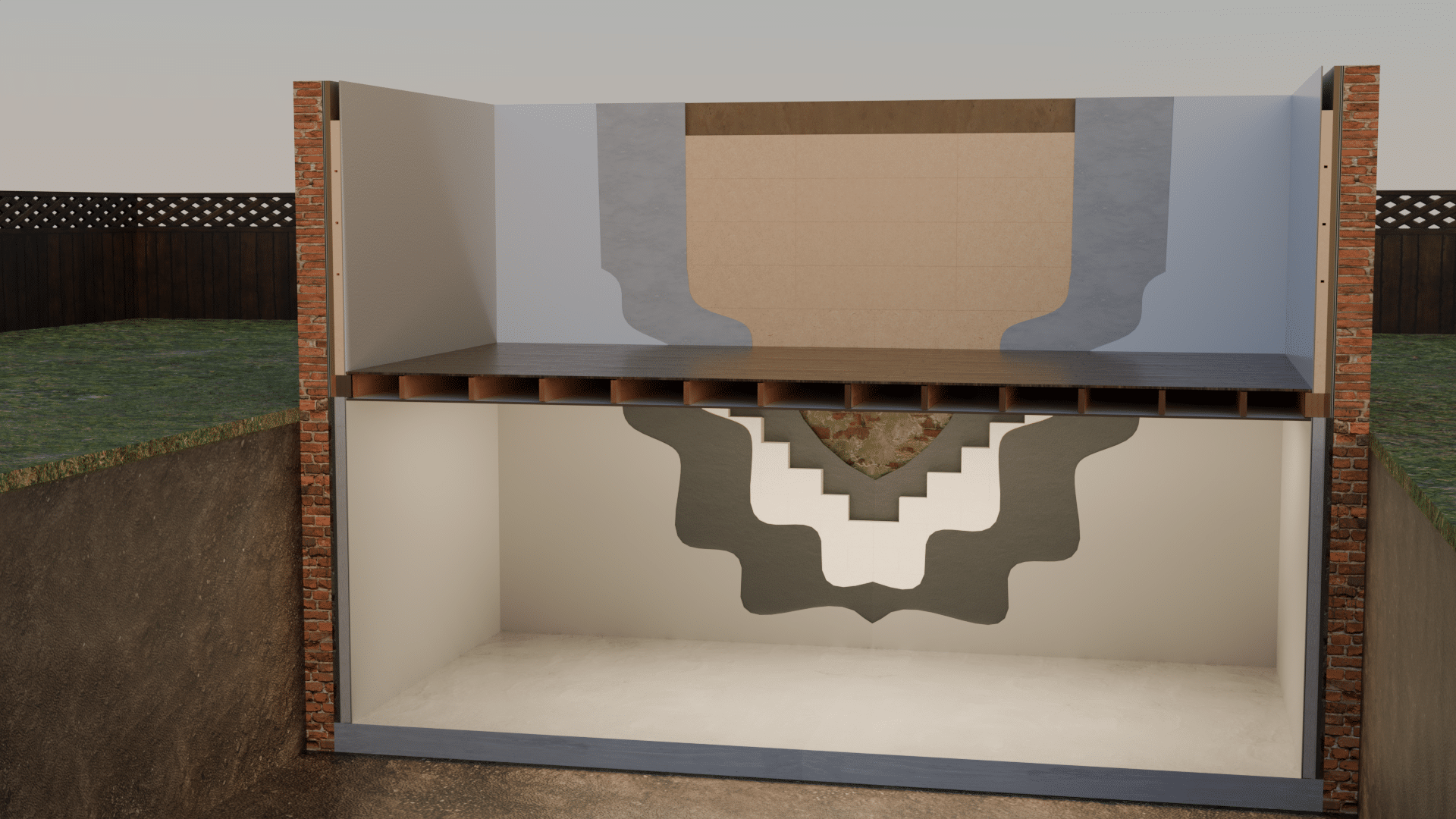

How to insulate walls below ground or basement walls.

Here, using some simple 3d models, we look at how to insulate walls below ground.

Below ground we would not usually recommend using natural fibre insulation as, no matter how well the wall is tanked, there is always a risk of moisture ingress and constantly high moisture levels within the insulation. Neither of these are beneficial for natural fibre insulation, as they can cause decay.

To find out exactly what materials are required for this process, if you don’t already, please visit our Specification Generator. This tool will give you a full specification based on the U-value target. If you’re still not sure, please contact us for more information.

Below-ground walls or basement walls with cementitious tanking or minimal moisture ingress

Where the walls are externally tanked with a drainage membrane or internally tanked with a cementitious tanking slurry, or if the walls are only ever a little damp and no water comes through them, you can simply insulate by applying the Multipor insulation to the interior

Step One

The surface of the walls should be well brushed down and/or washed down to remove any loose mortar/plaster, any salts and there should be no gypsum plaster on the surface of the wall. If the surface is bare masonry (e.g. not coated with a cement based plaster) a thin coat of Baumit SV61/Sanova Pre should be applied to the surface to create a key.

Step 2

The surface of the wall should be flat to enable the bonding of the Multipor boards and so if the surface of the walls needs levelling, use a coat of Multipor Fix X730 adhesive mortar/plaster.

Step 3

The Multipor ExSal Therm boards can now be applied directly to the walls. Starting at the base, apply a full coat of Multipor Fix X730 to the back of the Multipor boards. Combing the adhesive from left to right across the width of the boards, press them onto the wall surface 5mm or so from the adjacent board and slide into position up to the adjacent board. This 5-10mm slide closes up all of the air gaps behind the boards and ensures full contact with the wall behind.

The boards are installed in horizontal rows in a landscape orientation and in a brick-bond type pattern. Usually, what is cut off of the end of one row is used to start the next row and so on, until you reach the underside of the floor above.

Complete one wall at a time and when butting the boards of one face up to the other, apply a thin layer of Fix X730 between the boards to ensure no gaps are present. Once installed, lightly rub over any unevenness between boards with a new yellow polyurethane float or a grid plane to flatten out the surface. Do not use a nail float for this as it is far too aggressive.

Step 4

Once the Multipor boards have all been installed, you can apply the internal finish plaster. This consists of a 5-6mm layer of the Multipor Fix X730 adhesive plaster, combed with a knotched trowel, with a layer of the Baumit Startex mesh bedded into it.

Apply the Fix X730 to surface of the boards and comb with a 10mm knotched trowel. Ensure all of the ridges are fully filled as this ensures an even thickness of plaster across the surface of the boards. Whilst this is still wet, trowel in the Baumit Startex mesh (ensuring 100mm overlaps between rows) until it is no longer visible. Any trowel marks should be removed by lightly sponging the surface of the plaster.

Leave the base coat for 5-6 days before applying a 2-3mm coat of the Baumit RK70 N lime plaster or, if you’d prefer a finer finish (like Multi-finish) then use the Baumit Klima Glatte product.

If you have a suspended floor above the cellar/basement area and you are internally insulating the above ground walls, try and marry up the thickness of the Multipor boards with that of the wood fibre boards above. The junction between the two should be at least 200mm above ground and glued with the UdiSPECIAL Adhesive.

The Fix X730 plaster can come just up onto the wood fibre boards before switching to the Baumit RK70 N Lime plaster base coat or UdiMultigrund, depending on what is specified. Use an additional 300mm wide strip of mesh over the joint for additional reinforcement.

Services

Services should not be chased into the Multipor boards unless there is a minimum of 60mm behind the chase/conduit/back-box. Any services should be within plastic conduit and any back-boxes should also be within plastic housing. Back-boxes should be held in place with two Fischer FID-50 fixings.

Once the chase has been formed, it should be lined with a generous layer of the Multipor FIX X730 before the conduit/back-box is inserted into it. Let the excess FIX X730 squeeze out and trowel flat. Doing this ensures good airtightness around the conduit/back-box and prevents additional condensation forming within the wall.

Below-ground walls with no waterproofing

Where there is no external waterproofing and where there is water ingress periodically, we’d suggest using a meshed drainage membrane, such as Newtonite Lath Mesh Membrane. This needs to be well fixed back to the masonry wall with waterproof mechanical fixings. Although the fixings are said to be waterproof, there is always a small risk of moisture ingress and so the use of wood fibre insulation here is still not recommended.

The walls should be allowed to drain down to a perimeter floor drain or a fully drained sub-floor, such as our solid floor insulation specification. In a cellar/basement scenario, the upper layer of geotextile in the floor specification is replaced with the Newtonite lath membrane used in the walls to maintain water-tightness.

With the floor in place and the newton membrane fixed to the walls, the line of the walls should be checked for straightness. If they need to be straight and plumb then a levelling plaster of Baumit KZP 65 can be applied to straighten them.

Once prepared, you can adhesively fix the standard Multipor mineral insulation boards to the surface of the walls. You can only really adhesively fix insulation here as ordinary insulation fixings would puncture the membrane.

A 6-8mm layer (or 5mm if the surface has already been levelled) of Multipor Fix X710 is applied to the rear of the multipor boards using a notched trowel, the boards are pressed firmly against the membrane and slid slightly to the side. This ensures full bonding to the surface of the membrane and the elimination of any air voids behind.

This process is repeated, using a brick bonding pattern all the way up to the floor above, making sure the blocks reach right into the corners of the walls, ensuring no air voids are present behind the boards. The surface can then be plastered with a 5mm layer of the Multipor Fix X710, incorporating the Baumit StarTex mesh.

The plaster layer is the inner air tightness layer for the system and so this should join up to any airtightness layers in the floor below and in the case of a basement, to the floor above. Once the first coat of plaster has dried, this can be taped to any surrounding airtightness layers, as required.

If there is wood fibre insulation on the walls above this section and the plaster layer is passing straight from the surface of the Multipor to the wood fibre, use the Multipor Fix X710 to plaster in a row of mesh to span the joint by at least 300mm. Above this you can switch to the plaster used for the wood fibre boards.

Leave the base coat for 5-6 days before applying a 2-3mm coat of the Baumit RK70 N lime plaster or, if you’d prefer a finer finish (like Multi-finish) then use the Baumit Klima Glatte product.

If you have any questions about this installation, please feel free to contact us. Return to the Top