SPECIFICATION GENERATOR

Find out which low impact materials are right for your building project.

External Wall Insulation

Materials

Specification generator

Find out which low impact materials are right for your building project.

This following gives you an overview of all the components you’ll need to successfully install one of our external wall systems.

We have two systems for external wall insulation.

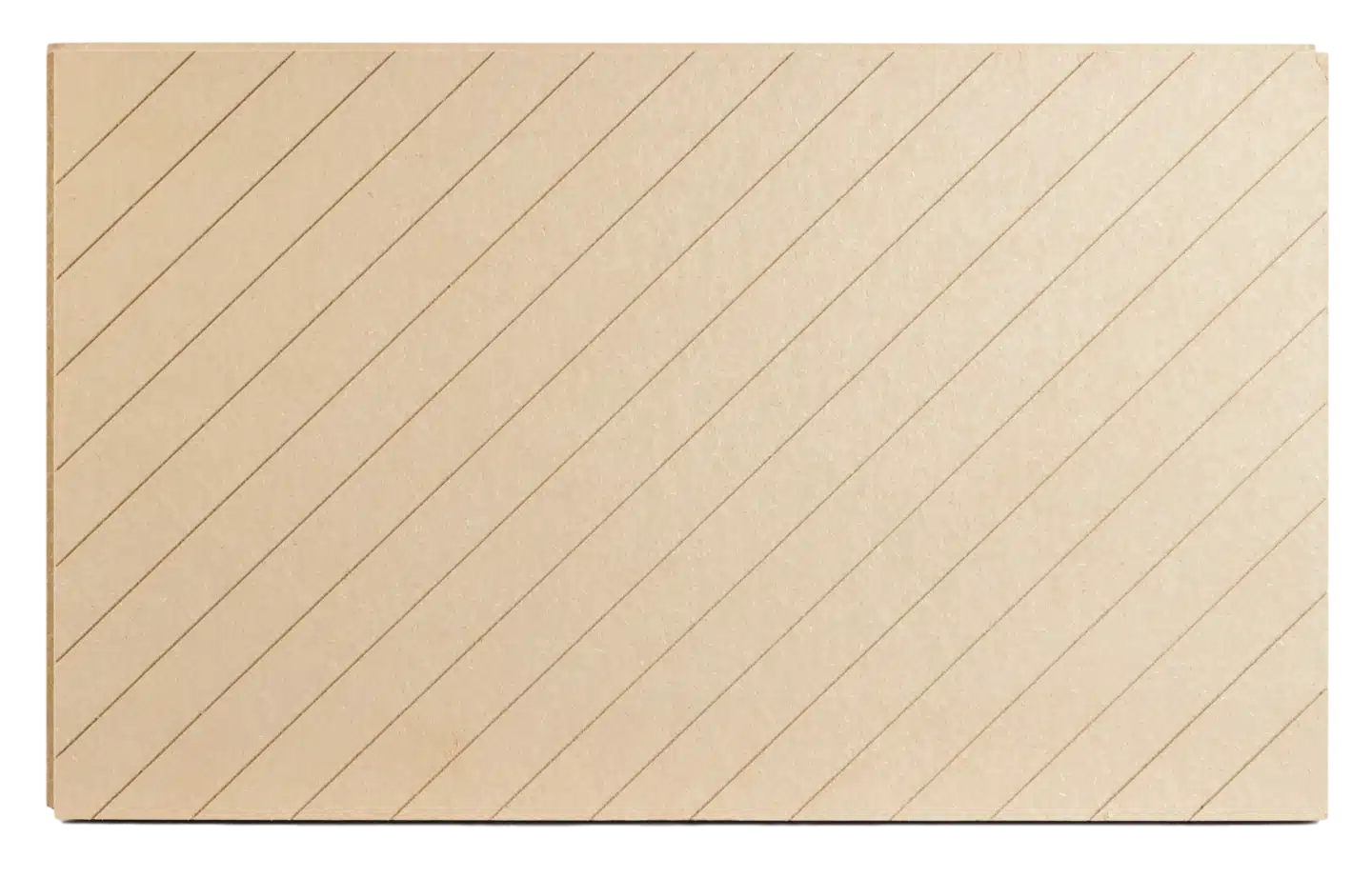

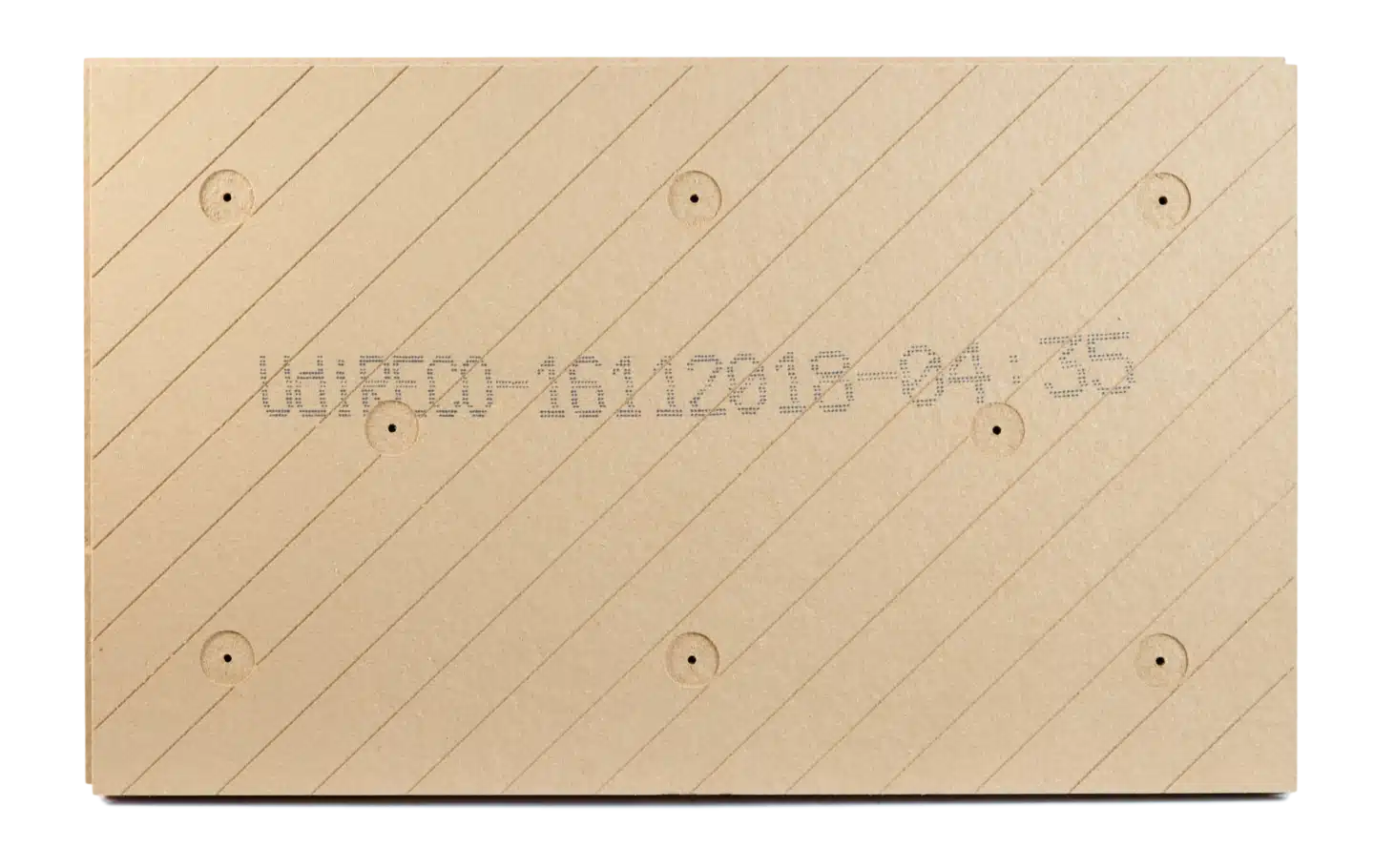

One uses the Diffutherm boards or the Beltermo Ultra boards and is perfect for flat surfaces and timber frames. The second is the UdiRECO system which is designed for uneven surfaces such as rendered or historic walls and also for uneven, part timbered surfaces.

Flat walls and timber frames

Thickness of board

If you’re choosing the Diffutherm or Beltermo Ultra system you’ll need to decide which thickness of boards you’ll need to use and this will depend on your target U-value. We recommend you allow 5-10% waste and assume that each board is roughly 1m². If you need to go thicker than 120mm then add a layer of UdiTHERM SK or Beltermo Kombi to the build-up which is fixed first.

Number and type of fixings

Once you’ve calculated how many boards you need, you’ll need to calculate the number of fixings required. If you’re fixing back to masonry you need the UdiASSEMBLY Masonry fixings for historic or soft substrates. High density substrates hold fixings better and so normal fixings, such as the Ejot STR-U fixings can be used or if on to timber then use the Ejot STR-H timber fixings. On masonry you’ll need 9 fixings per full board (per m2) and on timber you’ll need 8-9 per board, depending on the stud centres.

Uneven wall surfaces

Thickness of board

If you’re choosing the UdiRECO system choose the thickness that meets your U-value target. Its also worth checking the level of variation that you get in the surface of the wall as each board can only accommodate a maximum of 20% of it’s thickness. The boards go up to 200mm so will cope with 40mm variation in the surface and take your U-values down to 0.18 W/m²K. We recommend you allow 5-10% waste and assume that each board is roughly 1m².

Number and type of fixings

Once you’ve calculated how many boards you need you’ll need to calculate the number of fixings required. If you’re fixing back to masonry you need the UdiASSEMBLY Masonry fixings or if on to timber then use the UdiASSEMBLY Timber fixings. On masonry you’ll need 8 fixings per full board and on part timbered surfaces you’ll need 8-9 per board. Call us if you have any questions.

The rest of the system

Thermal bridging and openings

All the openings in the facades of both of the above systems need to lined with the 20mm reveal boards. These help form neat reveals and also reduce thermal bridging around the openings. You’ll need to use these boards to line the heads and sides of all openings but the cills don’t generally need it. Remember to include the full thickness of the insulation and the depth of the recess of the window. The reveal boards are 1350 x 500mm and are glued in place with the system adhesive. This adhesive is also required for all of the external corners in both systems.

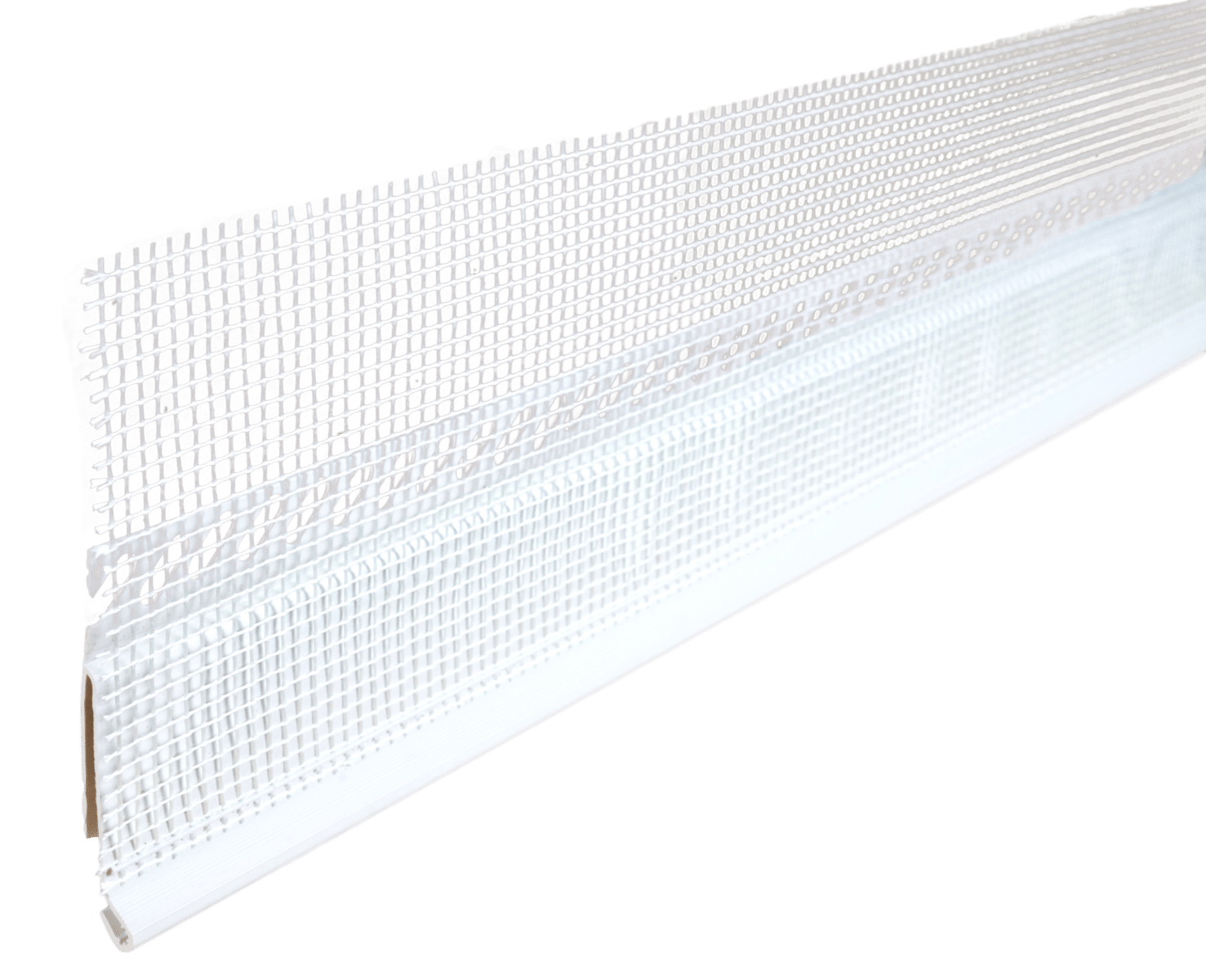

The plinth

Next you’ll need to look at all of the beads and trims. Along the base of the wall, for the UdiRECO system, you may need to use the UdiBASE plinth starter track and UdiBASE plinth edging strip to provide a robust base detail to the system. For the Diffutherm and Beltermo Ultra boards, on flat walling, you can use the Baumit plinth starter track. Alternatively you can use extruded polystyrene insulation (XPS), where it is less than 300mm above ground level.

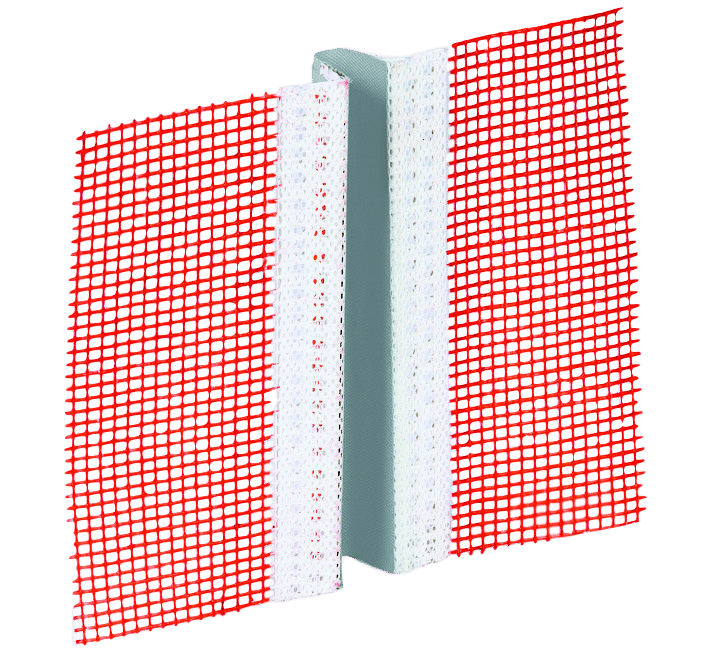

Beads and trims

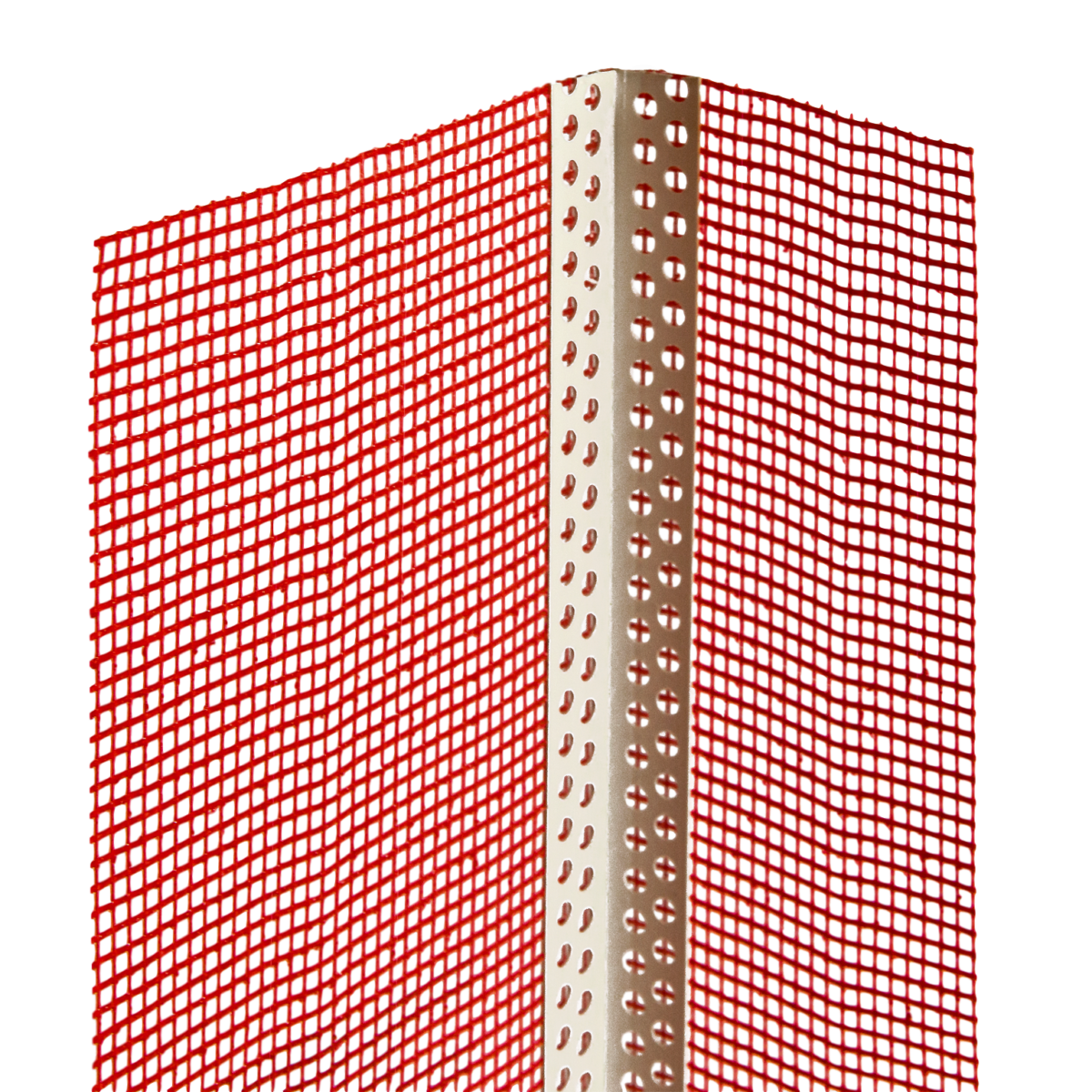

Around all of the openings you’ll need the UdiREINFORCEMENT render edging strips to create the join between the render and the door/window frames. Allow for the same linear meterage as the reveal boards above. Corner protection profiles are needed for the whole perimeter of windows, the heads and sides of doors and also for any external corners. Allow four of the arrow shaped corner strengthening mesh for each window and two for each door. Every opening will need two of the UdiREINFORCEMENT 3D corner reinforcement pieces.

And finally, rendering

Finally you’ll need the render to finish the systems off. The UdiRECO system uses the UdiFOUNDATION COAT render, which is applied at 5mm thickness with a half-round knotched trowel with the UdiREINFORCEMENT Mesh bedded in it. The Diffutherm system uses the Baumit MC55 render and the Baumit StarTex mesh bedded in it and applied at the same thickness. Each bag should cover at leat 3.5m2 at this thickness and the product is used from the ground up to the very top of the system. Where the render is less than 300mm below ground then it will need the UdiBASE plinth slurry or the Baumit DS26 Flex to prevent moisture from penetrating the system. Next, on the UdiRECO boards the UdiPERL primer is applied with a roller, followed by the UdiPERL finish render. On the Diffutherm you use the Baumit Premium Primer followed by the Baumit SilikonTop finish render

If you have any questions, please contact us.

Super-insulating Aerogel plaster – Fixit 222

£183.02+VAT per 50 litre bag (for approved contractor installation only)